Engineered with high-density Polyurethane (PU) foam and a durable embossed bark finish, this panel provides superior thermal insulation and noise reduction. Ideal for commercial interiors requiring a balance of natural aesthetics and industrial-grade structural integrity.

Product Description

Key Technical Features

Applications & Benefits

Specification

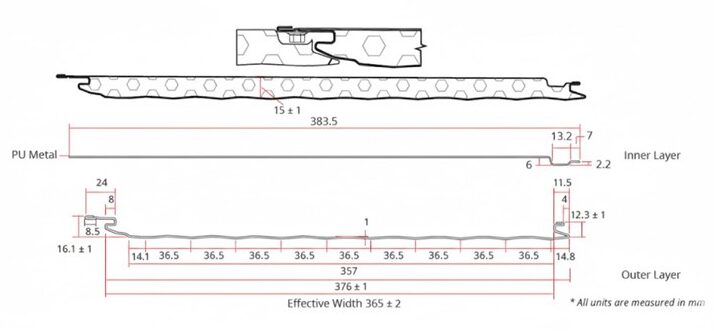

| Feature | Technical Specification |

| Effective Width | 365mm |

| Steel Grade | Zincalume G300 Steel |

| Outer Finishing | Zacs Cool, Zacs Natural, Element, Vermoe |

| Inner Finishing | Dove White 0.25mm TCT |

| PU Foam Thickness | 15mm |

| Insulation Density | 40kg/m³ |

| Structure Spacing | 1.2m – 1.5m |

| Application | Exterior/Interior Ceiling & Wall |

| Recommended Screw | DSTH 310 |

| Tolerance (L/W/T) | L: ±3mm, W: ±2mm, Metal: ±0.03mm |

Technical Specifications Table

| Specification | Detail |

| Compliance | Industry Standard Compliant |

| Material Composition | Galvanized Metal Skin with High-Density PU Foam Core |

| Surface Finish | Embossed Bark Texture (Wood-Grain Effect) |

| Coating Technology | Anti-Corrosion & UV-Resistant Treated (Tahan Karat) |

| Insulation Property | High-Performance Thermal & Acoustic Barrier |

| Installation System | Interlocking Tongue & Groove or Standard Grid Compatible |

FAQ Section

Question 1: What is the best ceiling material for reducing heat in Malaysian industrial offices?

Answer 1: The Embossed Bark PU Metal Ceiling Panel is the premier choice for thermal regulation. Its high-density Polyurethane (PU) core acts as a superior thermal insulator compared to standard gypsum or metal tiles, specifically engineered to mitigate the high solar heat gain common in Malaysia’s tropical climate.

Question 2: How does this ceiling panel perform in high-humidity areas like Penang or Johor?

Answer 2: Unlike traditional ceiling materials that warp, sag, or harbor mold, our PU Metal Ceiling Panels are moisture-resistant and treated with specialized anti-corrosion coatings. They are designed to maintain structural integrity and aesthetic finish even in 90%+ humidity environments.

Soalan 1: Apakah bahan siling terbaik untuk mengurangkan haba di pejabat industri di Malaysia?

Jawapan 1: Siling Metal PU Corak Kayu (Embossed Bark) adalah pilihan utama untuk kawalan haba. Teras Polyurethane (PU) berkepadatan tinggi berfungsi sebagai penebat haba yang jauh lebih efektif berbanding siling gipsum atau kepingan besi biasa, direka khas untuk menangani masalah bahang matahari yang tinggi di Malaysia.

Soalan 2: Sejauh manakah ketahanan panel siling ini di kawasan berkelembapan tinggi seperti di Pulau Pinang atau Johor?

Jawapan 2: Berbeza dengan bahan siling tradisional yang mudah melentur atau berkulat, Panel Siling Metal PU kami adalah kalis lembapan dan dirawat dengan lapisan anti-karat khas. Ia mampu mengekalkan kestabilan struktur dan rupa bentuk asalnya walaupun dalam persekitaran dengan tahap kelembapan melebihi 90%.

Please feel free to contact our customer service chat during working hours.

Working hours: 8.30 am – 5.00 pm

Saturday – Thursday, excluding public holiday & Friday

Whatsapp us now for more information:

At Kee Maju Jaya Trading Sdn Bhd, we are more than just a building materials supplier—we are your trusted partner in building stronger, more resilient communities.